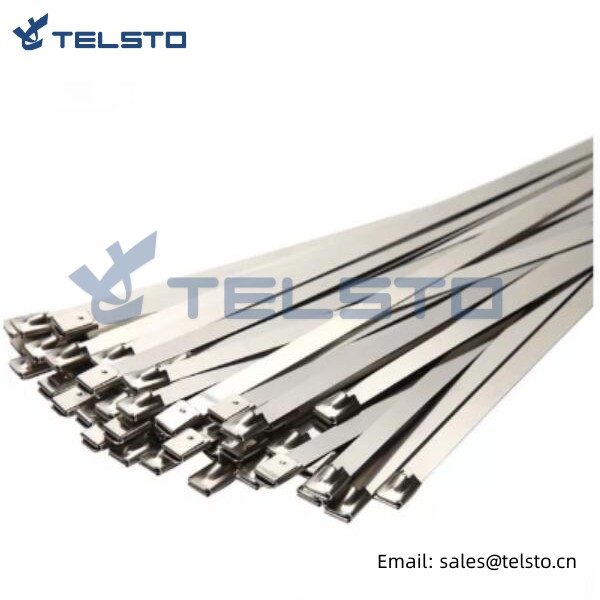

TEL-CTSC-4.6×300

| Material | #304 #316 stainless steel |

| Structure | Self locking, ball bearing mechanism for quick and easy installation,

either by hand |

| Working temperature | -80℃-500℃ |

| Length | All lengths are available |

| Feature | High tensile strength |

| Rust poof | |

| Non-flammability | |

| Anti corrosion | |

| High resistance to accidence, alkali acid, sulfuric acid, a corrode etc | |

| Certificate | RoHS |

| Usage | First, the cable is bundled in a stainless steel cable tie; |

| Next, the tail of the stainless steel band is clamped by the tool; | |

| Finally, tighten with tool | |

| Application | Shipbuilding, port, machinery, automobiles, aviation, electricity,

communications electronics,nuclear power,interurban locomotive and other industries |

| Delivery time | 3-15 days (Depend on your order quantity) after confirm order. |

| Payment terms | T/T, Western Union,L/C, PayPal |

| Product Name | Polyester Coated/Fully Polyester coated/Color Coated Stainless Steel self-locking Cable Ties ball lock type |

| Material | Stainless Steel Grade201, 304 or 316, etc; Stainless Steel grade 201 Suitable for indoor environment ; Stainless Steel grade 304 Suitable for outdoor environment; Stainless Steel grade 316 (marine grade) Suitable for extra corrosive environments; |

| Color | Black, red, yellow, green, Grey, etc; |

| Standard | ROHS |

| Package | A. Common Packing: 1000Pcs + Poly bag + Label + Export Carton. B. Customized Packing: Header card packing, Blister with card packing, Double blister packing, Canister packing; C. Package can also according customers' requests. |

| Product Features | 1)Install sexily and quickly 2)High tensile strength 3)Working Temp.: -80℃ to 150℃ 4) Fire-proof, UV-resistant ,non toxic and Halogen free 5)Coated band with non-toxic, halogen free polyester coating 6)Provides additional edge protection 7)Prevents the corrosion between dissimilar materials. 8)Metallic buckle helps to distinguish from black nylon tie. 9)High resistance to acetic acid, alkali acid, sulfuric acid,anti-corrosion,etc; |

| Application | Stainless steel cable ties are a quick effective way of securing cables.Utilized in general use banding application They can be used in virtually petrochemical, food industry, industries, power stations, mining, ship-building, offshore and any other aggressive environments, etc. |

| Delivery Term | EXW, FOB, CFR, CIF, etc. |

Installation Instructions of N or 7 / 16 or 4310 1 / 2″ super flexible cable

Structure of connector: ( Fig1 )

A. front nut

B. back nut

C. gasket

Stripping dimensions is as shown by diagram ( Fig2 ), attention should be paid while stripping:

1. The end surface of inner conductor should be chamfered.

2. Remove impurities such as copper scale and burr on the end surface of the cable.

Assembling the sealing part: Screw the sealing part in along the outer conductor of the cable as shown by the diagram ( Fig3).

Assembling the back nut (Fig3).

Combine the front and back nut by screwing as shown by diagram ( Figs( 5)

1. Before screwing, smear a layer of lubricating grease on the o-ring.

2. Keep the back nut and the cable motionless, Screw on main shell body on back shell body. Screw down main shell body of back shell body using monkey wrench. Assembling is finished.