Stainless Steel Banding Buckle

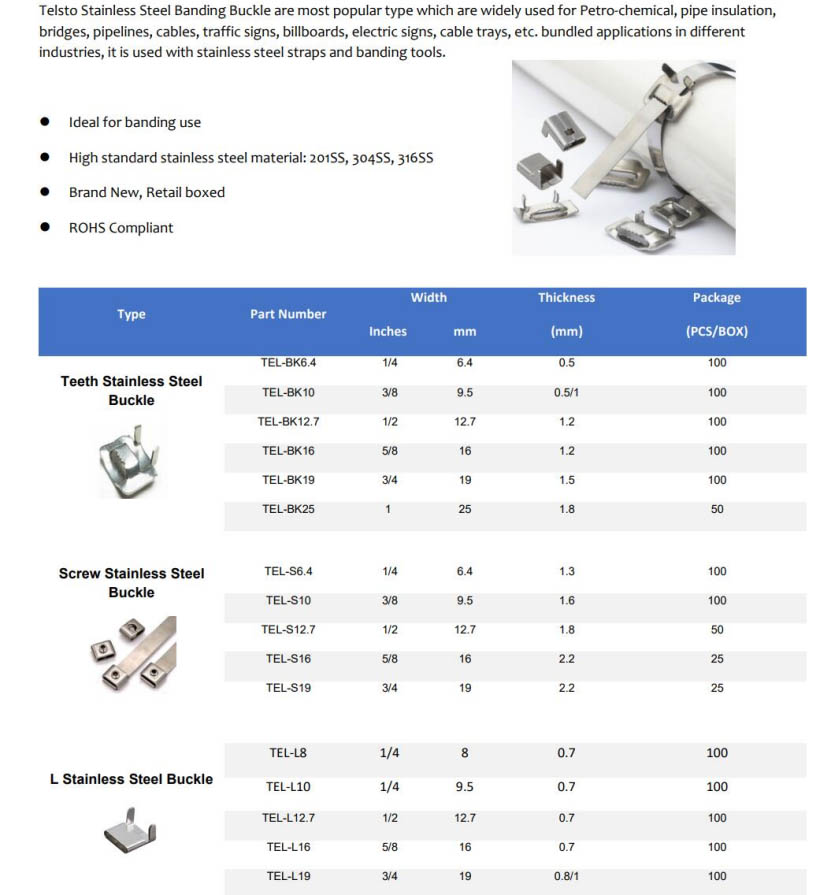

Telsto Stainless Steel Banding Buckle are most popular type which are widely used for petro- chemical, pipe insulation, bridges, pipelines, cables, traffic signs, billboards, electric signs, cable trays, etc. bundled applications in different industries, it is used with stainless steel straps and banding tools.

|

Type |

Part Number |

Width |

Thickness |

Package |

|

|

Inches |

mm |

||||

|

Teeth Stainless Steel Buckle |

TEL-BK6.4 |

1/4 |

6.4 |

0.5 |

100 |

|

TEL-BK10 |

3/8 |

9.5 |

0.5/1 |

100 |

|

|

TEL-BK12.7 |

1/2 |

12.7 |

1.2 |

100 |

|

|

TEL-BK16 |

5/8 |

16 |

1.2 |

100 |

|

|

TEL-BK19 |

3/4 |

19 |

1.5 |

100 |

|

|

TEL-BK25 |

1 |

25 |

1.8 |

50 |

|

|

Screw Stainless Steel Buckle |

TEL-S6.4 |

1/4 |

6.4 |

1.3 |

100 |

|

TEL-S10 |

3/8 |

9.5 |

1.6 |

100 |

|

|

TEL-S12.7 |

1/2 |

12.7 |

1.8 |

50 |

|

|

TEL-S16 |

5/8 |

16 |

2.2 |

25 |

|

|

TEL-S19 |

3/4 |

19 |

2.2 |

25 |

|

|

L Stainless Steel Buckle |

TEL-L8 |

1/4 |

8 |

0.7 |

100 |

|

TEL-L10 |

1/4 |

9.5 |

0.7 |

100 |

|

|

TEL-L12.7 |

1/2 |

12.7 |

0.7 |

100 |

|

|

TEL-L16 |

5/8 |

16 |

0.7 |

100 |

|

|

TEL-L19 |

3/4 |

19 |

0.8/1 |

100 |

|

Installation Instructions of N or 7 / 16 or 4310 1 / 2″ super flexible cable

Structure of connector: ( Fig1 )

A. front nut

B. back nut

C. gasket

Stripping dimensions is as shown by diagram ( Fig2 ), attention should be paid while stripping:

1. The end surface of inner conductor should be chamfered.

2. Remove impurities such as copper scale and burr on the end surface of the cable.

Assembling the sealing part: Screw the sealing part in along the outer conductor of the cable as shown by the diagram ( Fig3).

Assembling the back nut (Fig3).

Combine the front and back nut by screwing as shown by diagram ( Figs( 5)

1. Before screwing, smear a layer of lubricating grease on the o-ring.

2. Keep the back nut and the cable motionless, Screw on main shell body on back shell body. Screw down main shell body of back shell body using monkey wrench. Assembling is finished.