SS 304 Ear Lock Stainless Steel Buckle for Banding Strap

| Name | SS 304 Ear Lock Stainless Steel Buckle for Banding Strap |

| Color | naked |

| Thickness | 0.4mm 0.5mm 1mm 1.5mm 2mm |

| Width | 8mm 10mm 12mm 16mm 19mm |

| Packing | 100Pcs/packing with label |

| Feature | Acid and Corrosion Resistant |

| OEM | accepted |

| Usage | Banding application |

| Delivery time | 1~3 days according to your quantity |

| Temperature | -60~+150 |

| Customize | accepted |

Product Feature:

1. Ear-Lock Buckles can be used with many types of stainless steel band providing fastening strength.

2. Ear-Lock style buckle for standard duty applications including hose assemblies, cable banding and general fastening.

3. 201/304/316 Stainless Steel offers good resistance to oxidation and many moderate corrosive agents.

4. You can hold a single or double wrapped band configuration.

5. Band clamps can be formed over any contour shape.

|

Type |

Part Number |

Width |

Thickness |

Stainless Steel Material |

Package |

|

mm |

(mm) |

(pcs/pack) |

|||

|

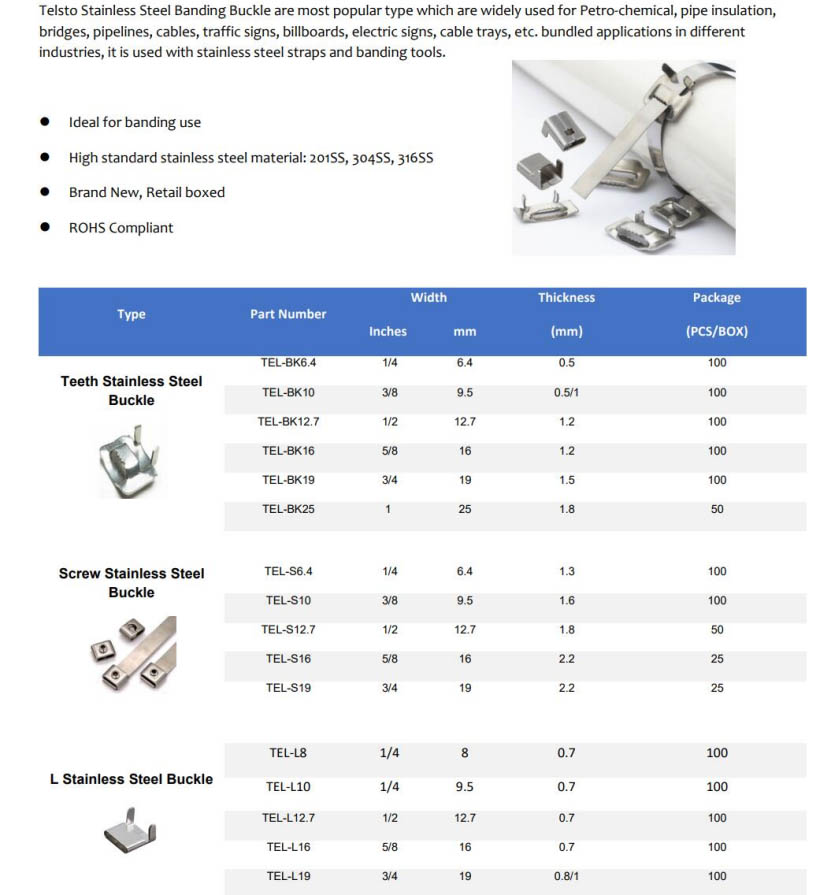

Teeth Stainless Steel Buckle |

TEL-BK-32X2.4 |

32 |

2.4 |

201/304 |

100 |

| TEL-BK-25X2.4 |

25 |

2.4 |

201/304 |

100 |

|

| TEL-BK-19X2.4 |

19 |

2.4 |

201/304 |

100 |

|

| TEL-BK-19X1.5 |

19 |

1.5 |

201/304 |

100 |

|

| TEL-BK-19X1 |

19 |

1 |

201/304 |

100 |

|

| TEL-BK-16X1.5 |

16 |

1.5 |

201/304 |

100 |

|

| TEL-BK-16X1 |

16 |

1 |

201/304 |

100 |

|

| TEL-BK-12.7X1 |

12.7 |

1 |

201/304 |

100 |

|

| TEL-BK-12.7X1.5 |

12.7 |

1.5 |

201/304 |

100 |

|

| TEL-BK-10X1.2 |

10 |

1.2 |

201/304 |

100 |

|

| TEL-BK-10X1 |

10 |

1 |

201/304 |

100 |

|

|

L Stainless Steel Buckle |

TEL-LBK-10X0.7 |

10 |

0.7 |

201/304 |

100 |

| TEL-LBK-20X1 |

20 |

1 |

201/304 |

100 |

|

| TEL-LBK-6.4X0.7 |

6.4 |

0.7 |

201/304 |

100 |

|

| TEL-LBK-20X1 |

20 |

1 |

201/304 |

100 |

|

| TEL-LBK-19X1 |

19 |

1 |

201/304 |

100 |

|

| TEL-LBK-16X1 |

16 |

1 |

201/304 |

100 |

|

| TEL-LBK-12.7X0.8 |

12.7 |

0.8 |

201/304 |

100 |

Installation Instructions of N or 7 / 16 or 4310 1 / 2″ super flexible cable

Structure of connector: ( Fig1 )

A. front nut

B. back nut

C. gasket

Stripping dimensions is as shown by diagram ( Fig2 ), attention should be paid while stripping:

1. The end surface of inner conductor should be chamfered.

2. Remove impurities such as copper scale and burr on the end surface of the cable.

Assembling the sealing part: Screw the sealing part in along the outer conductor of the cable as shown by the diagram ( Fig3).

Assembling the back nut (Fig3).

Combine the front and back nut by screwing as shown by diagram ( Figs( 5)

1. Before screwing, smear a layer of lubricating grease on the o-ring.

2. Keep the back nut and the cable motionless, Screw on main shell body on back shell body. Screw down main shell body of back shell body using monkey wrench. Assembling is finished.