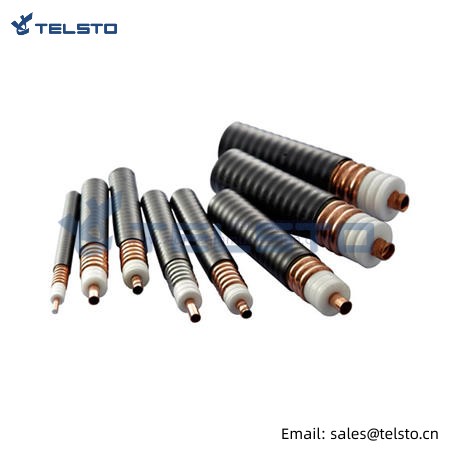

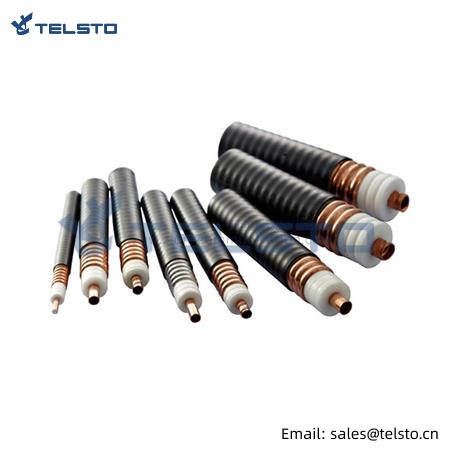

Hansen feeder cable 78 low loss

Model Number: RF Feeder Cable

Construction Characteristics:

High physically foaming insulation, copper tape formed, welded and corrugated to manufacture the outer conductor

Inner Conductor: Smooth Copper Tube/ Copper Coating Aluminum/ Helix Copper Tube

Dielectric: Physical Foaming Polyethylene(PE)

Outer Conductor: Corrugated Copper Tube/ Angularity Copper Tube/ Helix Copper Tube

Jacket: Black PE or Low Smoke Halogen-free Fire-retardant

Advantages:

Low attenuation, low standing wave, high shielding, damp-proof gas free maintenance, flexible, high anti tensile strength.

Application Range:

Broadcast and television, microwave telecommunication, military use, aerospace, vessel or other circumstance where RF cable is needed.

You can choose:

| Type | Characteristic Impedance(Ohm) | Inner Conductor (mm) |

Insulation (mm) |

Outer Conductor (mm) |

Outer Sheath (mm) |

Attenuation at 900MHz (dB/100m) |

Attenuation at 1800MHz (dB/100m) |

| 1/4" SF | 50 | 1.90 | 5.00 | 6.40 | 7.60 | 18.40 | 27.10 |

| 1/4" | 50 | 2.60 | 6.00 | 7.70 | 8.90 | 13.10 | 19.10 |

| 3/8" SF | 50 | 2.60 | 7.00 | 9.00 | 10.20 | 13.50 | 19.70 |

| 3/8" | 50 | 3.10 | 8.00 | 9.50 | 11.10 | 10.90 | 16.00 |

| 1/2" SF | 50 | 3.55 | 9.00 | 12.00 | 13.70 | 10.00 | 14.50 |

| 1/2" | 50 | 4.80 | 12.00 | 13.90 | 16.00 | 7.15 | 10.52 |

| 5/8" | 50 | 7.00 | 17.00 | 19.70 | 22.00 | 5.07 | 7.54 |

| 7/8" F | 50 | 9.40 | 22.00 | 24.90 | 27.50 | 4.05 | 6.03 |

| 7/8" SF | 50 | 9.40 | 22.00 | 24.90 | 27.50 | 4.30 | 6.30 |

| 7/8" | 50 | 9.00 | 22.00 | 24.90 | 27.50 | 3.87 | 5.84 |

| 7/8" Low Loss | 50 | 9.45 | 23.00 | 25.40 | 28.00 | 3.68 | 5.45 |

| 1-1/4" | 50 | 13.10 | 32.00 | 35.80 | 39.00 | 2.82 | 4.27 |

| 1-5/8" | 50 | 17.30 | 42.00 | 46.50 | 50.00 | 2.41 | 3.70 |

Packing Reference

Installation Instructions of N or 7 / 16 or 4310 1 / 2″ super flexible cable

Structure of connector: ( Fig1 )

A. front nut

B. back nut

C. gasket

Stripping dimensions is as shown by diagram ( Fig2 ), attention should be paid while stripping:

1. The end surface of inner conductor should be chamfered.

2. Remove impurities such as copper scale and burr on the end surface of the cable.

Assembling the sealing part: Screw the sealing part in along the outer conductor of the cable as shown by the diagram ( Fig3).

Assembling the back nut (Fig3).

Combine the front and back nut by screwing as shown by diagram ( Figs( 5)

1. Before screwing, smear a layer of lubricating grease on the o-ring.

2. Keep the back nut and the cable motionless, Screw on main shell body on back shell body. Screw down main shell body of back shell body using monkey wrench. Assembling is finished.