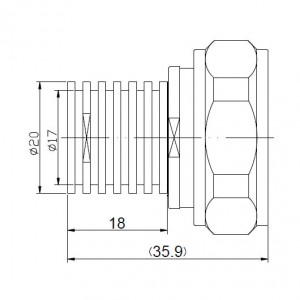

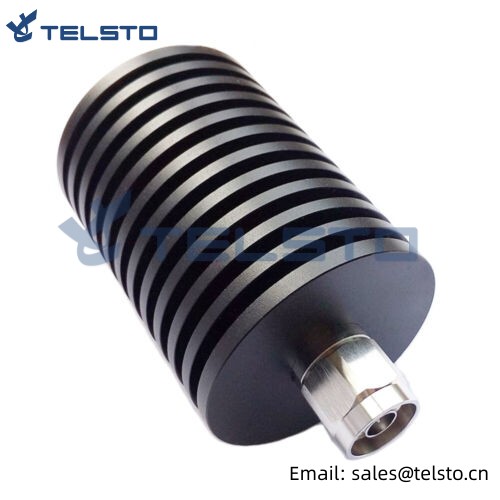

DIN Male Type load 1W

Application

Mobile Communication Network Optimization and Indoor distribution system.

Cluster Communication, Satellite Communication, Shortwave Communication and Hopping Radio.

Radar, Electronic Navigation and Electronic Confrontation.

Aerospace Equipment systems.

| Material and Plating | |

| Center contact | Brass / Silver Plating |

| Insulator | PTFE |

| Body & Outer Conductor | Brass / alloy plated with tri-alloy |

| Gasket | Silicon Rubber |

| Electrical Characteristics | |

| Characteristics Impedance | 50 Ohm |

| Frequency Range | DC~6 GHz |

| Working Humidity | 0-90% |

| Insertion Loss | 0.08-0.12 @3GHz-6.0GHZ |

| VSWR | 1.08-1.2@3GHZ-6.0GHZ |

| Temperature range ℃ | -35~125 |

Features

● Multi-band version for DC-3GHz

● High reliability

● Low VSWR

● Ideal for BST applications

● N & 7 /16 DIN male/female connectors

| Product | Description | Part No |

| Termination Load

|

N Male /N Female, 2W | TEL-TL-NMF2WV |

| N Male/N Female, 5W | TEL-TL-NMF5W | |

| N Male/N Female, 10W | TEL-TL-NMF10W | |

| N Male/N Female, 25W | TE-T- NMF 2W | |

| N Male/N Female, 50W | TEL-TL-NMF50W | |

| N Male/N Female, 100W | TEL-TL-NMF100W | |

| DIN Male/ Female, 10W | TEL-TL-DINMF10WV | |

| DIN Male/Female, 25W | TEL-TL-DINMF25W | |

| DIN Male/ Female, 50W | TEL-TL-DINMF50W | |

| DIN Male/ Female, 100WV | TEL-TL-DINMF100WV |

| Part No. | Frequency Range (MHz) | lmpedance(O) | Power Rating(W) | VSWR | Temperature Range(°C) |

| TEL-TL-NM/F2W | DC-3GHz | 50 | 2 | 1.15: 1 | -10-50 |

| TEL-TL-NM/F5W | DC-3GHz | 50 | 5 | 1.15: 1 | -10-50 |

| TEL-TL-NM/F10W | DC-3GHz | 50 | 10 | 1.15: 1 | -10-50 |

| TEL-TL-NM/F25W | DC-3GHz | 50 | 25 | 1.15: 1 | -10-50 |

| TEL-TL-NM/F50W | DC-3GHz | 50 | 50 | 1.15: 1 | -10-50 |

| TEL-TL-NM/F100W | DC-3GHz | 50 | 100 | 1.25: 1 | -10-50 |

| TEL-TL-DINM/F10W | DC-3GHz | 50 | 10 | 1.15: 1 | -10-50 |

| TEL-TL-DINM/F25W | DC-3GHz | 50 | 25 | 1.15: 1 | -10-50 |

| TEL-TL-DINM/F50W | DC-3GHz | 50 | 50 | 1.15: 1 | -10-50 |

| TEL-TL-DINM/F100W | DC-3GHz | 50 | 100 | 1.25: 1 | -10-50 |

Packing Reference

Installation Instructions of N or 7 / 16 or 4310 1 / 2″ super flexible cable

Structure of connector: ( Fig1 )

A. front nut

B. back nut

C. gasket

Stripping dimensions is as shown by diagram ( Fig2 ), attention should be paid while stripping:

1. The end surface of inner conductor should be chamfered.

2. Remove impurities such as copper scale and burr on the end surface of the cable.

Assembling the sealing part: Screw the sealing part in along the outer conductor of the cable as shown by the diagram ( Fig3).

Assembling the back nut (Fig3).

Combine the front and back nut by screwing as shown by diagram ( Figs( 5)

1. Before screwing, smear a layer of lubricating grease on the o-ring.

2. Keep the back nut and the cable motionless, Screw on main shell body on back shell body. Screw down main shell body of back shell body using monkey wrench. Assembling is finished.